Products

Home > Products > Brushless dc motor > BM Brushless DC Motor and Drive

Brushless DC Motor and DC Drive |

||

| Product applications: | ||

| Golf car、Tractor、Minivan、Forklift、LSV、Go cart、E-pedicab、E-scooter、E-bike、Lawn mower, etc. | ||

Brushless DC Motor is particularly designed of using with NdFeB magnets to perform high power and torque density, and small size structure. It is good for EV, Electric Vehicle and battery power applications. High efficiency, wide speed range, low EMI and no brush maintenance are Brushless DC Motor benefits. |

||

| 1. | Energy efficiency Brushless DC motor adopts the high magnetic energy permanent magnet to have high power and torque density, and small size structure. | |

| 2. | Innovating structure to have high torque performance. | |

| 3. | Electrical commutation can perform low noise, low EMI and no brush maintenance. | |

| 4. | Lower rotor inertia and good heat dissipation, Our winding of Brushless DC Motor is in the stator. The winding of brush-type motor is in the rotor. | |

| 5. | Power and torque density are much higher than the conventional motors. | |

| 6. | Without mechanical commutation, DC motor speed can be over 10,000 rpm. | |

| 7. | The innovating structure has an excellent feature in energy saving during heavy-load operation, and high torque at low speed driving. The high efficiency range is much wider than conventional AC motors. | |

| 8. | The DC drive adopts the full functions for E-vehicle needs. Ex. Battery low voltage protection, alarms, safety switch, FWD/REV, run/stop. | |

Brushless DC Motor VS. Induction Motor VS. Brush Motor |

| Topic | Brushless DC Motor | Induction Motor | DC Brush Motor |

| Compact Size, Light Weight | ◎ | X | △ |

| Low Rotor Inertia, High Speed Rotation |

◎ | △ | X |

| No Rotor Copper Lose | ◎ | X | △ |

| High Efficiency | ◎ | △ | △ |

| Heat Dissipation | ◎ | △ | X |

| No Carbon & Electric Flash | ◎ | ◎ | X |

| Low Speed Torque | ◎ | X | △ |

| No Brush Maintenance | ◎ | ◎ | X |

| Over Load Capability | ◎ | X | △ |

| ◎ Excellent △ Acceptable X Poor | |||

| Drive Functions | Drive protections |

|

|

Brushless DC Motor Specifications |

|

|

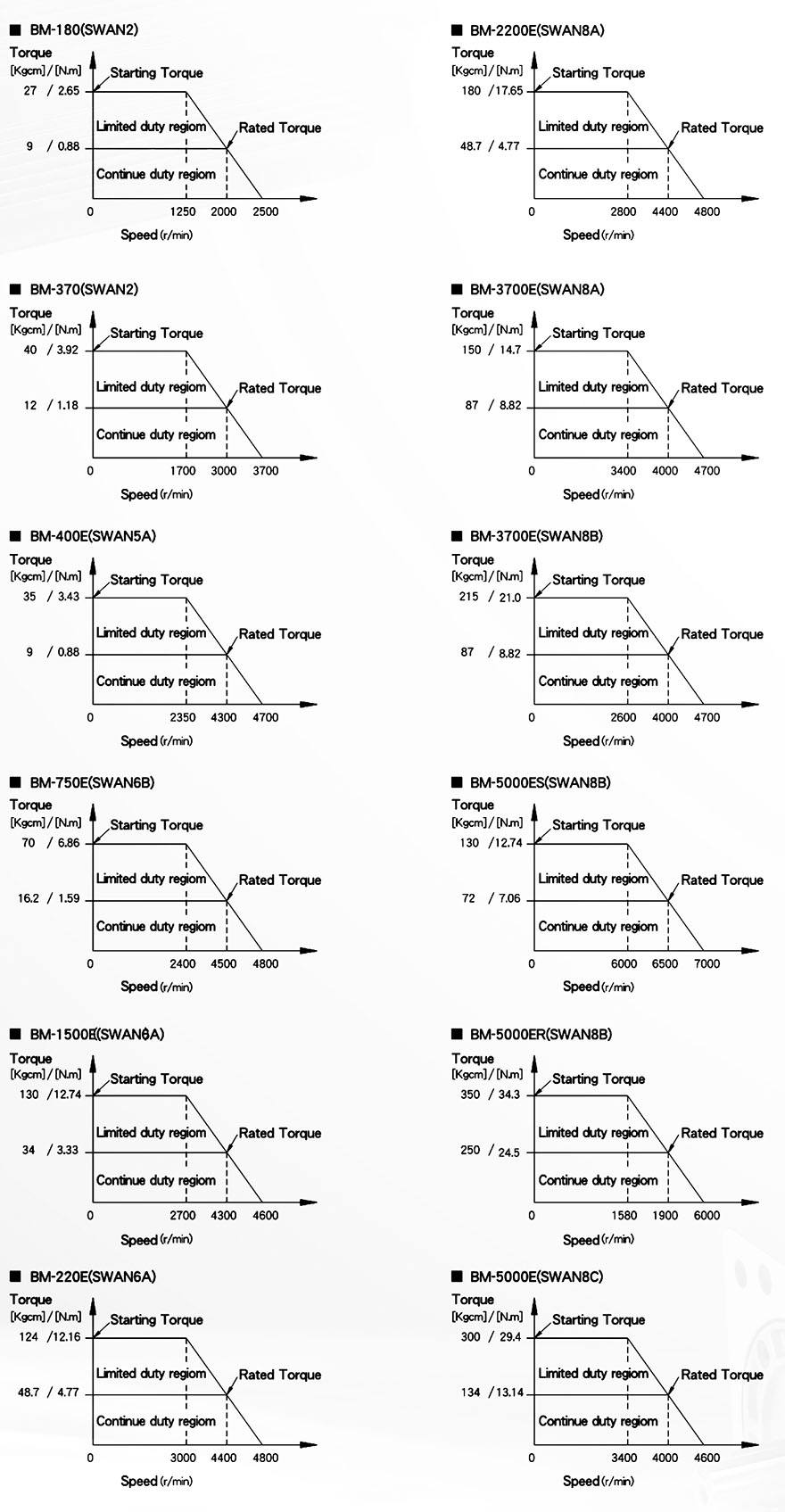

BM-180 | BM-370 | BM-400E | BM-750E | BM-1500E | ||

| Drive Model No. | SW02 | SW02 | SW05A | SW06B | SW06A | ||

|

24 | 24 | 48 | 48 | 48 | ||

|

180 | 370 | 400 | 750 | 1500 | ||

|

9 | 12 | 9 | 16.2 | 34 | ||

|

27 | 40 | 35 | 70 | 130 | ||

|

9.0 | 19.0 | 9.7 | 18.6 | 36.0 | ||

|

25 | 50 | 29 | 57 | 106 | ||

|

2000 | 3000 | 4300 | 4500 | 4300 | ||

|

2500 | 3700 | 4700 | 4800 | 4600 | ||

|

280 | 650 | 800 | 2100 | 3700 | ||

|

Fig. 1 | Fig. 3 | Fig. 5 | Fig. 7 | Fig. 8 | ||

|

Fig. A | Fig. A | Fig. C | Fig. D | Fig. E |

|

BM-2200E | BM-3700E | BM-5000ES | BM-5000ER | BM-5500E | ||

| Drive Model No. | SW06A/SW09A | SW08A/SW09B | SW09B | SW09B | SW09C | ||

|

48 | 48 | 48 | 48 | 72 | ||

|

2200 | 3700 | 5000 | 5000 | 5500 | ||

|

48.7 | 90 | 72 | 250 | 134 | ||

|

124/180 | 150/215 | 130 | 350 | 300 | ||

|

48 | 87 | 114 | 140 | 89 | ||

|

106/140 | 140/200 | 200 | 220 | 200 | ||

|

4400 | 4000 | 6500 | 1900 | 4000 | ||

|

4800 | 4700 | 7000 | 6000 | 4600 | ||

|

3700/5200 | 5200/5800 | 8000 | 5700 | 10500 | ||

|

Fig. 8 | Fig. 9 | Fig. 11 | Fig. 12 | Fig. 10 | ||

|

Fig. E/F | Fig. F | Fig. F | Fig. F | Fig. F |

Brushless DC Servo Motor Specifications |

|

BM-180E | BM-370E | BM-550E | BM-750E | ||

| Drive Model No. | SWAN2V202 | SWAN2V204 | SWAN5V205 | SWAN6V407 | ||

|

24 | 24 | 24 | 48 | ||

|

30 | 30 | 30 | 60 | ||

|

180 | 370 | 550 | 750 | ||

|

6.1 | 12.2 | 18.1 | 24.4 | ||

|

16.8 | 34.2 | 77.3 | 69.8 | ||

|

9.3 | 18.6 | 27.6 | 18.6 | ||

|

26.1 | 52 | 77 | 52 | ||

|

3000 | 3000 | 3000 | 3000 | ||

|

Fig. 2 | Fig. 4 | Fig. 6 | Fig. 7 | ||

|

Fig. B | Fig. B | Fig. C | Fig. E |

|

BM-1500E | BM-2200E | BM-3700E | ||

| Drive Model No. | SWAN6V415 | SWAN6V422 | SWAN9V437 | ||

|

48 | 48 | 48 | ||

|

60 | 60 | 60 | ||

|

1500 | 2200 | 3700 | ||

|

48.8 | 73.2 | 122 | ||

|

136.64 | 205 | 340 | ||

|

36 | 48 | 87 | ||

|

101 | 134.4 | 244 | ||

|

3000 | 3000 | 3000 | ||

|

Fig. 8 | Fig. 8 | Fig. 9 | ||

|

Fig. E | Fig. E | Fig. F |

Motor Dimensions |

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 6

Fig. 7

Fig. 8.9.10

Unit: mm

| Fig. No. | □P | ØM | ØS | ØN | T | L | LA | LB | LC | LD | LE | AA | AB | AC | AD | Shaft End | ||||||

| ED | Q | E | ØD | GA | F | DH | ||||||||||||||||

| Fig. 8 | 130 | 145 | 9 | 110 | 3.5 | 288.5 | 12 | 238.5 | 27 | 143 | 219.5 | 82.5 | 93.5 | 116 | 68.6 | 45 | 50 | 50 | 24 | 27 | 8 | M8X24L |

| Fig. 9 | 180 | 200 | 13.5 | 114.3 | 4 | 359.5 | 18 | 280.5 | 74 | 261.5 | 116.5 | 141 | 63 | 73 | 79 | 35 | 38 | 10 | M12X25L | |||

| Fig. 10 | 454.5 | 341.5 | 135 | 322.5 | 90 | 108.5 | 113 | 42 | 45 | 12 | M16X32L | |||||||||||

Fig. 11

Fig. 12

Drive Dimensions |

|

Performance ( Torque Control ) |

Performance ( Speed Control ) |